Quality Control

The ultimate test on the performance of any musical equipment remain the listening experience in our home. From a technical standpoint however the result also need to be quantified accurately to confirm that the requested specification has been met. The equipment used to manufacture our idler wheels are also used to create parts in the aerospace industry requiring very tight tolerances capable of producing high precision components right down to the micron level - the very best in the business. This level of precision can't be analyzed by human eye or standard measuring equipment so we rely on advanced measuring techniques to comply and deliver the certificate of conformity required at the end of a production run.

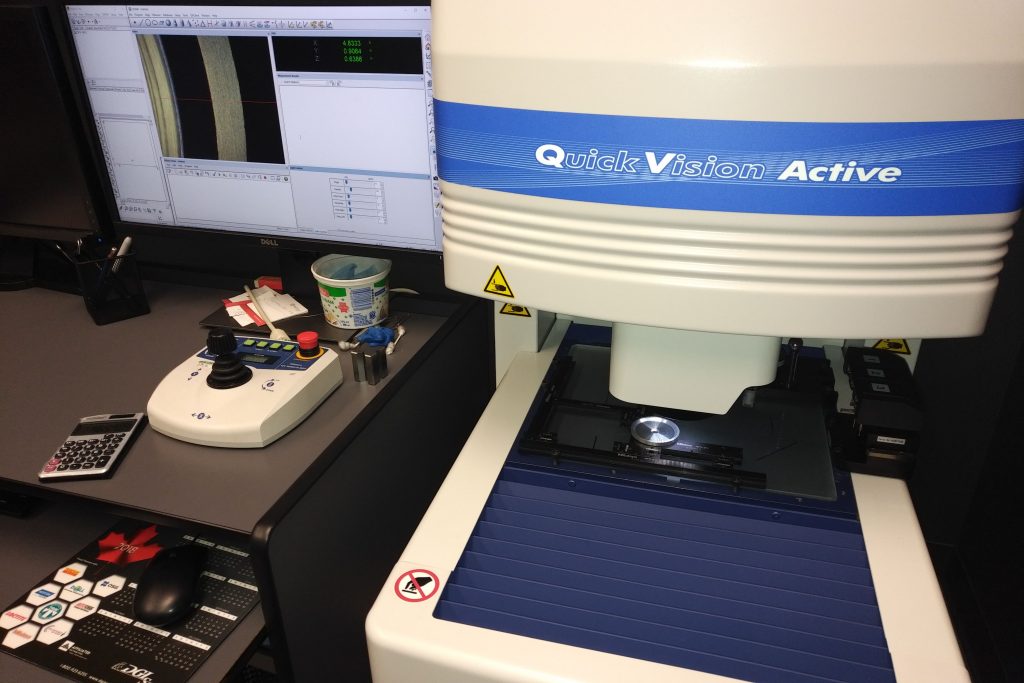

Here we see our DUAL 1219/1229/1229Q idler wheel placed on a CMM flat bed for highly accurate measurements and analysis required to deliver its Certificate of Conformity.

Manufacturing Certification

At the start of a production run the first wheel is removed from the line and gets measured using high performance Coordinate-Measuring Machines (CMM) to ensure that each part not only conforms to the required specification but also guarantees consistency within the produced parts so that they each perform equally as good as the next.

Our Dual 1219/1229/1229Q idler wheel is placed on precision blocks and measured with a test indicator to visually identify any surface roughness variation relative to its faces.

Spot Checking

Wheels are randomly selected while in production so they can be verified by various methods such as inspection on a Granite Surface Plate as shown here to measure the quality of the run.

Our DUAL 10/12 series idler wheel concentricity is put to the test using a precision test pin installed inside the bushing and a dial indicator between its ID (bushing) and OD (rubber) components.

System Concentricity

Once the wheel is fully assembled the rubber tire is ground to the aluminium base and the completed wheel is checked:

- Spin wheel counter-clockwise while checking for needle movement

- Raise needle to confirm actual reading is live

- Spin wheel clockwise and check again

FREE Shipping

over *$99 CAD (*conditions apply)

Made In Canada

Aerospace grade manufacturing process guarantees or exceeds OEM specifications for high precision parts

Wholesale Pricing

The more you buy the more you save "Bundle Pricing" rebates

Secure Payments

Peace of mind shopping as our website is totally encrypted for secure transactions